Early Television CRT Rebuilding WorkshopNick Williams, who spent two weeks in France studying the RACS rebuilding procedure, was in Hilliard from August 7th through the 10th to run a rebuilding workshop. August 7: Today was focused on getting the glass welding equipment working. The horizontal lathe was aligned by adjusting the feet. Neck welding will be done on this lathe. The vertical lathe from Hawkeye will be used for stem installation. A gas leak was detected and fixed. The wire heating device for cracking the neck glass was repaired (transformers had burned out and were replaced).

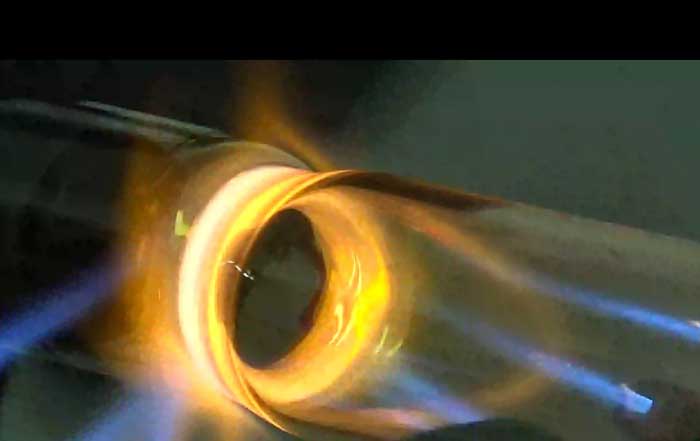

August 8: After some experimentation, Nick was able to use the horizontal lathe to weld flares to the end of several tubes.

Max installed the pumps under the oven. He had previously cleaned them. August 9: Nick attempted to install buttons/stems in two tubes. The first resulted in a large crack. The second looked good, but a hairline crack on the stem was discovered.

Max continued to work on the pumps and began programming the oven controller for the proper ramp up/ ramp down times and temperatures. Steve installed a sump pump and plumbing for the drain of the wash tub. Steve completed some remaining items on the oven, including replacing a bad solid state relay, removing the induction heating coil inside the oven, wiring the heating element for the diffusion pump, and installing the water lines from the diffusion pump to outside. August 10: Nick and Max discovered that when the diffusion pump was connected to the mechanical pump and the vacuum measured with the mechanical pump turned on it didn't produce the proper vacuum. It was determined that the diffusion pump must have a small leak. We determined that the Hawkeye pump would fit, and we installed it and tested the vacuum, which was fine. Max then cleaned the Hawkeye pump. Steve discovered that the bombarder wouldn't heat a gun to a high enough temperature to flash the getter. In addition, Nick prefers to use a wand rather than the flashing box. It was decided that we would use the bombarder from Hawkeye, so we unloaded it from the trailer and connected it to a 240 volt circuit. Tomorrow we will connect the wand and test it. John Yurkon told us that the tipoff coil that Hawkeye used requires 24 vac rather than the 8 that our power supply is designed for. Tomorrow we will modify it. If all goes well we will attempt a rebuild. August 11: A very frustrating day, but with a good ending. We tried three different diffusion pumps. The first two resulted in vacuums without the diffusion pump turned on of about 5 torr, while about 20 millitor is what we should have gotten. On our final attempt, we got a reading of 200 millitorr, so we turned on the diffusion pump. After replacing the wrong heating element (230 v rather than 120) and dealing with a water leak in the pump cooling (not yet fixed), we finally got a reading of 50 millitorr, better, but not nearly good enough. After discussion with John Yurkon, we concluded that our vacuum measuring equipment wasn't working properly. So, we may have been successful in getting a good enough vacuum for tube rebuilding, but didn't know it. We are sending our measuring stuff to John for him to check and calibrate. He is sending us back a diffusion pump we had loaned him earlier, John has cleaned and checked this one. Steve got the Hawkeye bombarder working, and connected the wand.

Nick was successful in installing a button/stem in a tube, and Steve got the Hawkeye bombarder working. So, once we determine that the vacuum is working, we will attempt to finish the rebuilding process.

Nick is on his way home. Thanks to Nick and Max for their many hours they put into this project.

The new controller (right side of oven). The Color Champion bombarder has been removed since we will no longer use it.

|