Postwar Television

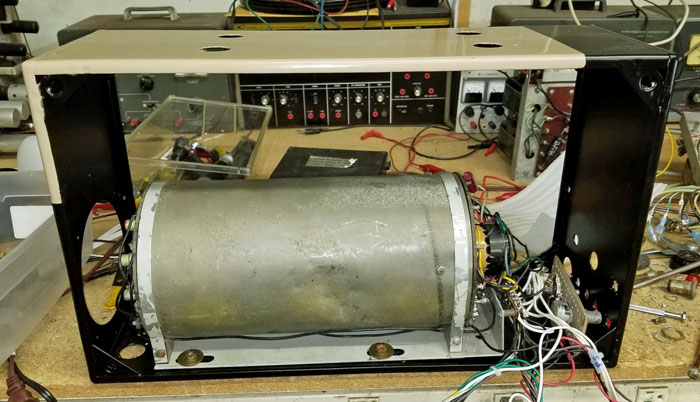

Diamond Power Image Dissector Camera

This camera was made in the early 50s by the Diamond Power Specialty Co. of Lancaster, Ohio. We don't know the model number, but the camera was preceeded by the model 300, which uses octal tubes, and was made in 1950. It uses an image dissector tube, and was made to monitor boilers in power plants. The image dissector had very poor light sensitivity, but it was ideal for high light levels such as the flames inside a boiler. The image dissector tube in this camera was made by Diamond. We have started restoration of the camera. Here is a video about Diamond Power and the tube: The camera has its own count-down sync generator, with both video and RF output.

The camera was used with monitors that displayed an unusual aspect ratio. They may have been made to display the size of the viewing aperture on the boiler. The camera and monitors were donated to the museum by Jean Roundhouse, whose husband Richard was a radio and television engineer in Lancaster and Columbus.

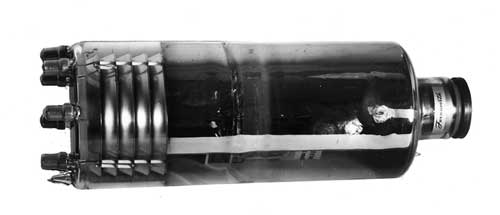

Through the generosity of Tom Genova, we were able to acquire an original image dissector tube for this camera. It is named Utilicon, and was made by Diamond Power.

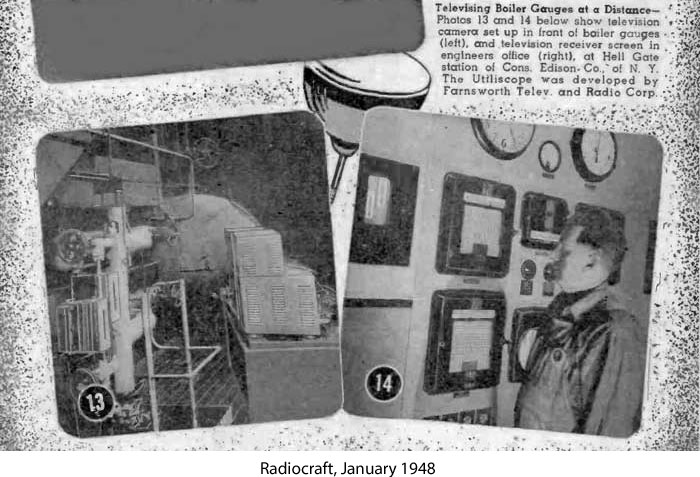

A similar tube made by Farnsworth Here is a note from Don Stephenson, a design engineer at Diamond Power:

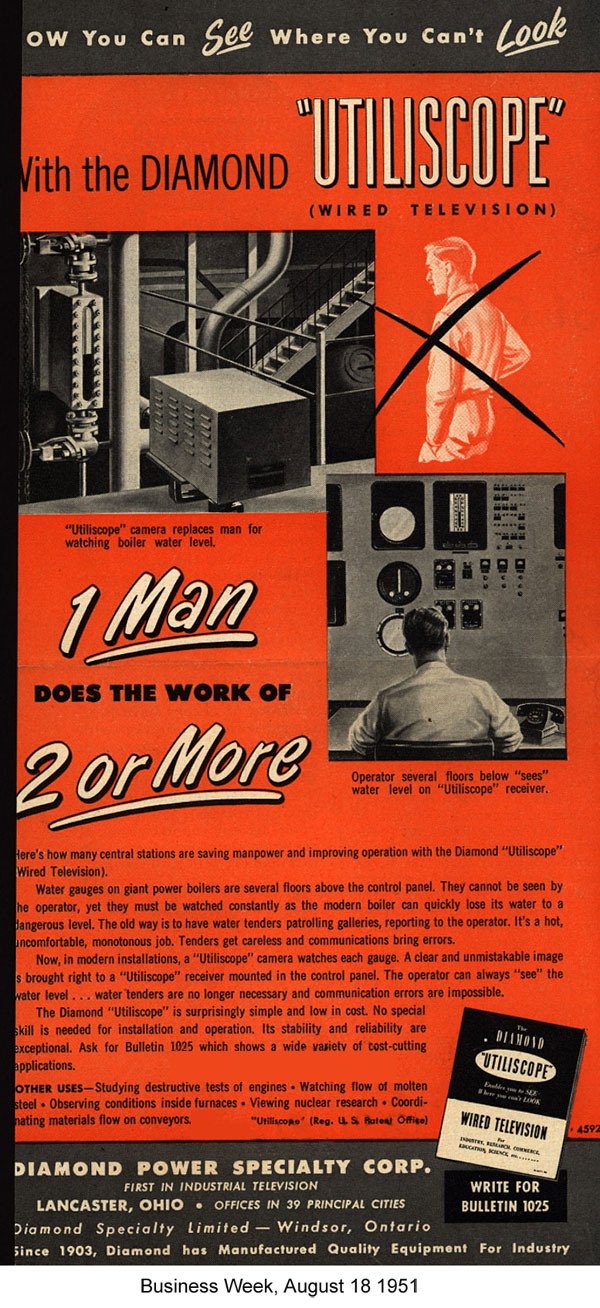

Model 100-1 Courtesy of Duke University Libraries Ad*Access |