Early Television

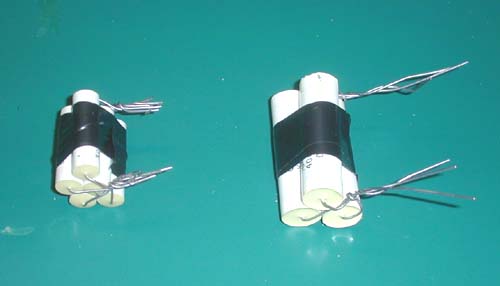

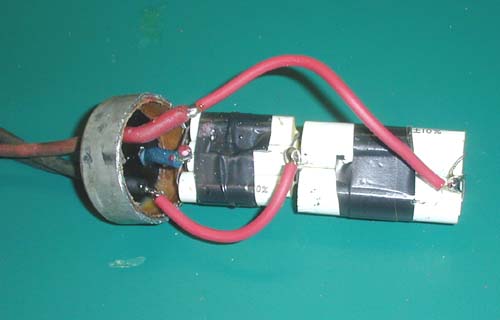

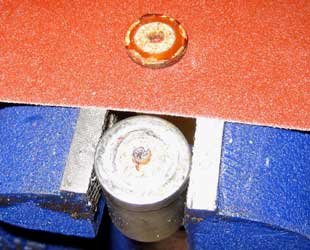

Rebuilding High Voltage (EHT) CapacitorsOften the high voltage (EHT) capacitors in early electronic sets are bad. They can be rebuilt using modern parts inside the old cans. Here is the process I use. Can Style First, the capacitor is opened up. In this case the can is mounted to the chassis with a bracket around its base. The can is cut so that the cut will be hidden by the bracket when installed. For screw mounted capacitors the procedure described in the section on rebuilding electrolytics can be used to open the can. Next, the guts are removed. In this case, two holes were drilled in the material inside the can, then the jaws of needlenose pliers were used to remove the material. A heat gun melted the wax at the end. Then, modern capacitors are grouped together to provide the values needed. This capacitor had a .05/3000 volt and a .15/3000 volt section. For the .05 section, 5 - .01/4000 volt capacitors were used. For the .15 section, 3 - .05/4000 volt capacitors were used. The assembly is connected to the existing leads. Instrument wire, with a rating of 6KV, is used. The center wire is ground (earth). The assembly is wrapped in high voltage insulating cambric cloth to assure it doesn't arc to the can. Finally, a glue gun is used to apply hot glue to the fabric and the two pieces of the can. After cleaning the can is ready to be re-installed. Cylindrical Soldered Can Style

|